Precision Manufacturing—On Time & On Spec

Every component meets international standards and arrives right on schedule.

Our Core Capabilities

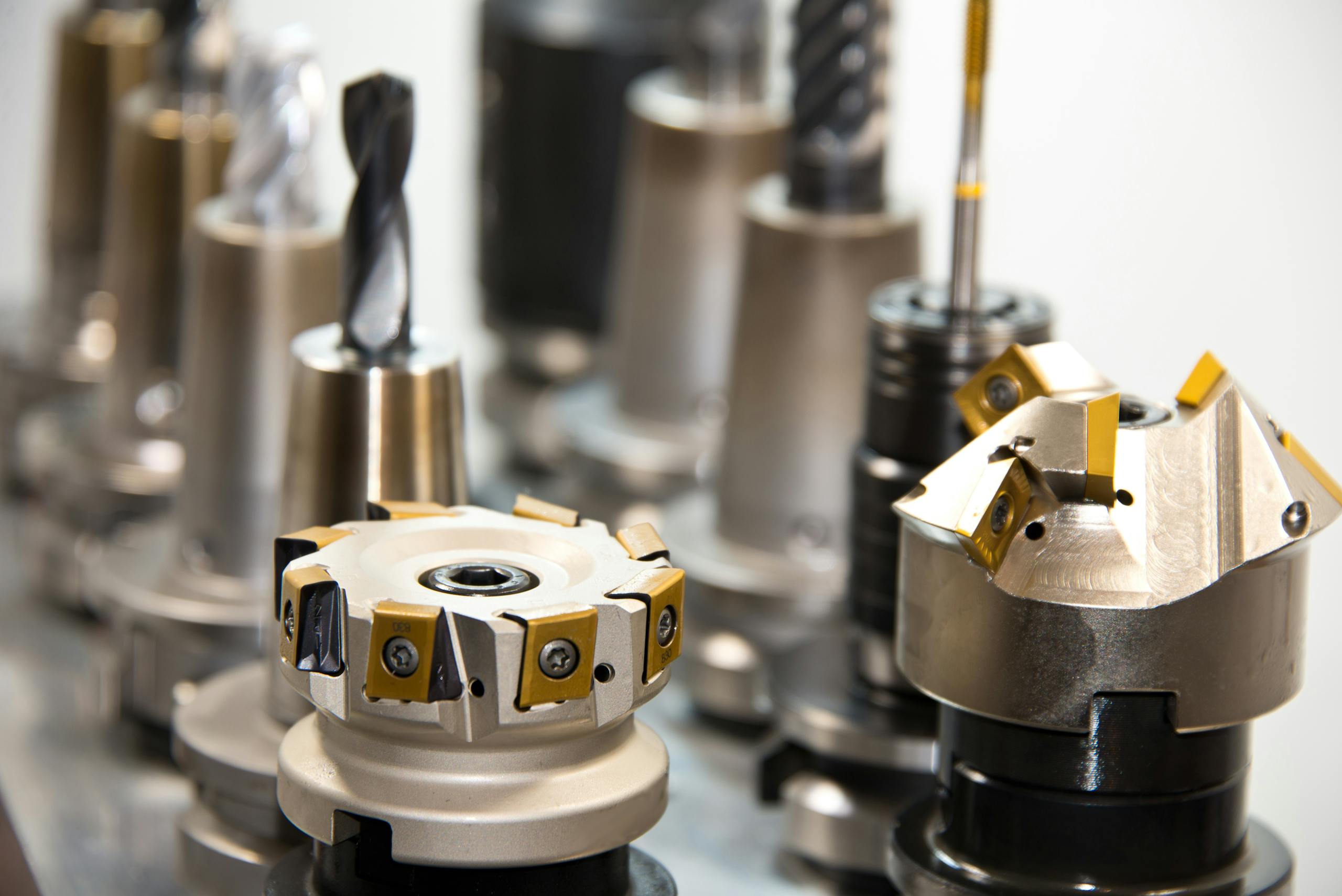

CNC Machinig

Precision milling and turning for complex parts, backed by consistent process control and reliable lead-times.

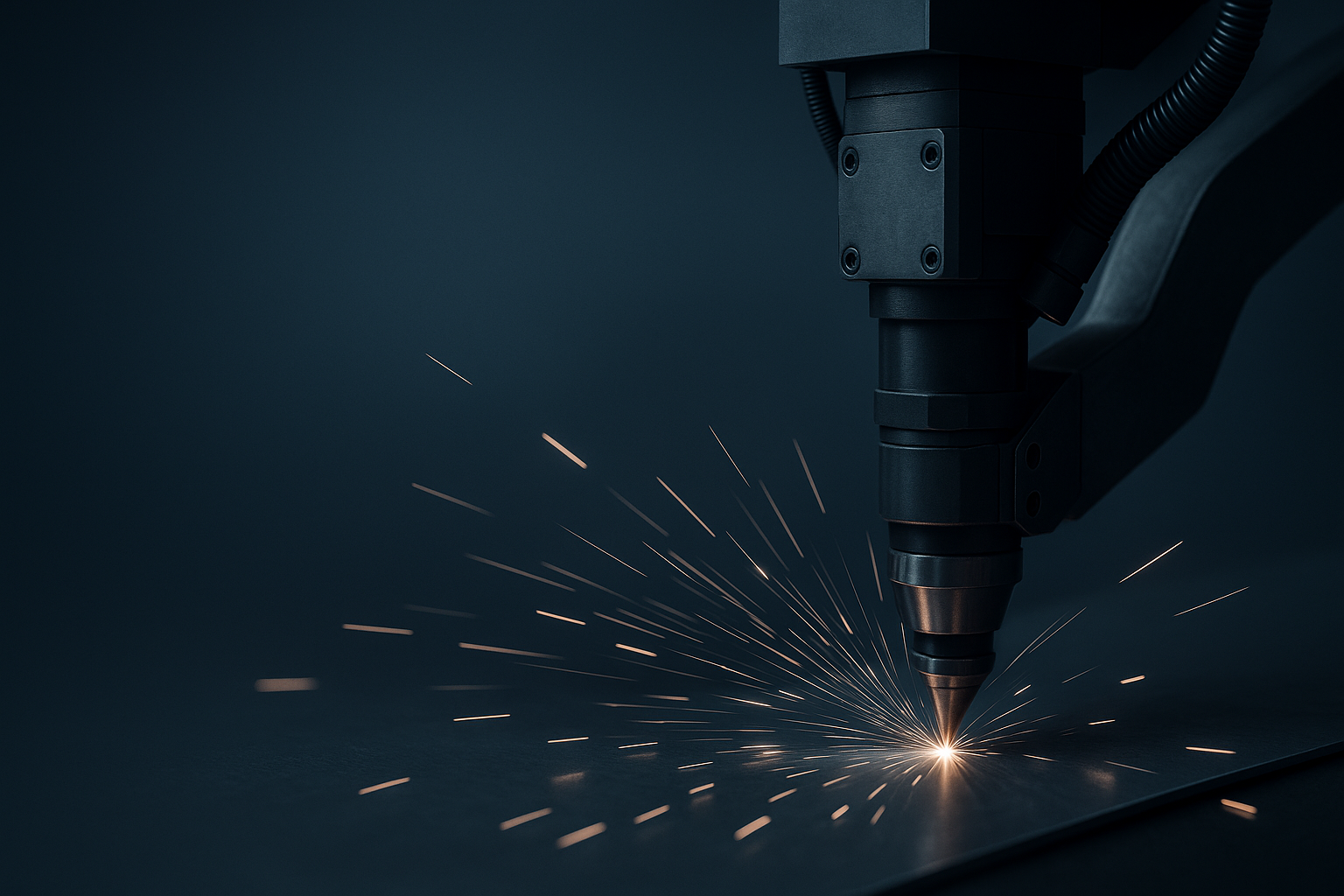

Precision Fabrication

End-to-end sheet-metal services—cutting, forming, and finishing—delivering crisp, repeatable results for any geometry.

Certified Welding

Skilled, code-compliant welders create structurally sound joints in a wide range of ferrous and non-ferrous alloys.

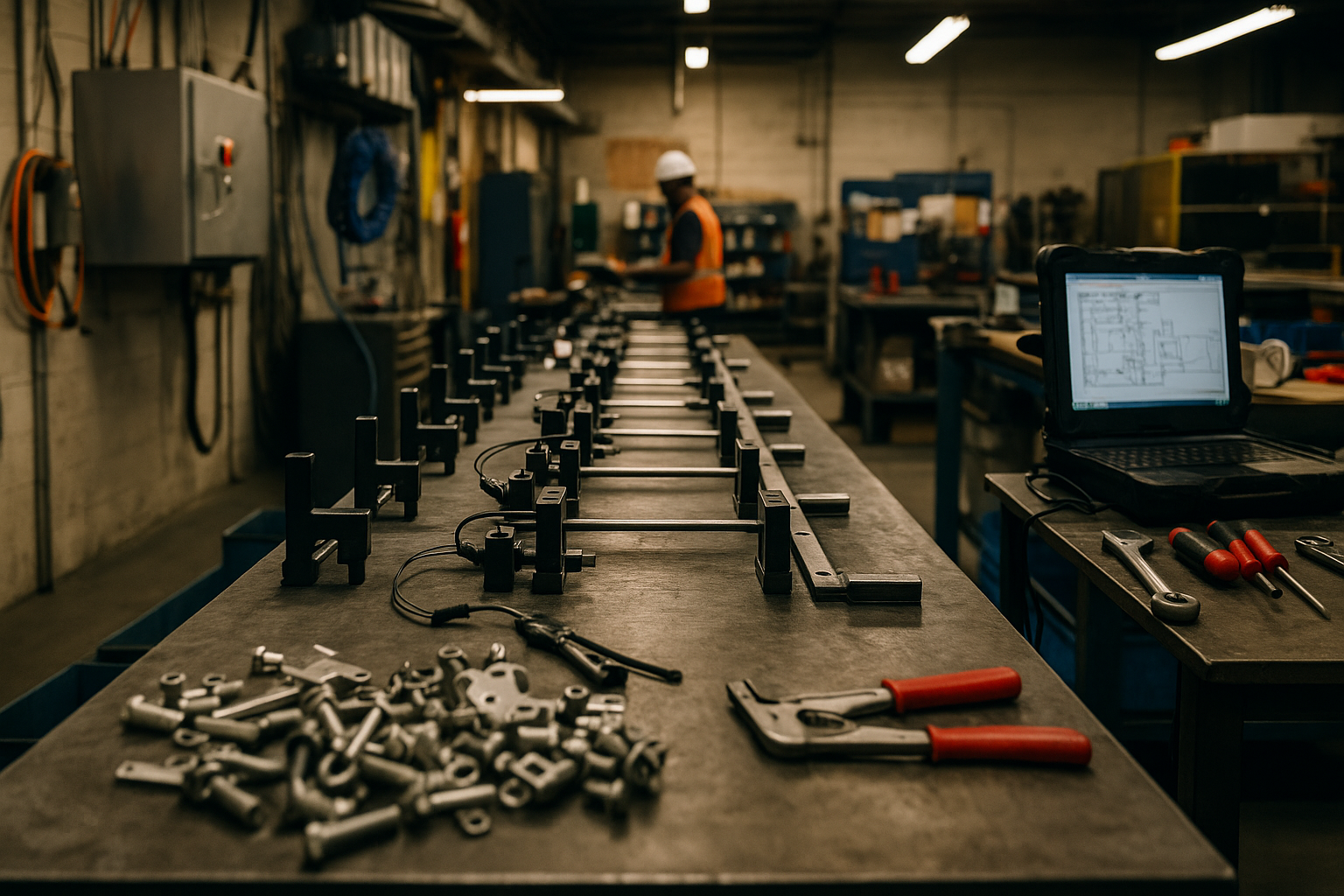

Assembly & Kitting

Mechanical and electro-mechanical sub-assemblies packaged as ready-to-install kits to streamline your production flow.

Pipe Fabrication

Custom-cut, code-compliant pipe spools and assemblies produced to spec for fluid and gas applications..

Tube Bending & Forming

Precision mandrel bending and end-forming deliver tight-radius or complex tubing with repeatable accuracy.

Fittings Manufacturing / Supply

Machined or stock fittings supplied to ANSI / ASME standards, ready for immediate system integration.

Industrial Hardware Supply

Fasteners, seals, and specialty hardware kitted and traceable—streamlining your build and spare-parts inventory.

PRODUCT GROUPS

Defence

Low-volume components engineered for assured field readiness.

Medical Industry

Precision parts meeting exacting clinical requirements.

Industrial Equipment

Reliable machining for heavy-duty industrial operations.